surface treatment technnology

Anti-rust treatment that doesn’t harm people or the environment Zero Chromium

As hexavalent chromium, which is contained in chromate filming agents used in zinc plating, has a harmful effect on the environment, we have been asked passionately for a chromium free anti-rust treatment agent. Responding to this need, our company, as a result of much diligent research in techniques, found that tannic acid and a specific metallic compound combined to form an anti-corrosive film. From this, a highly corrosive resistant rust proofing technique (patent no. 3337134), which is not harmful to people or the environment, was established.

Strong points

- It is completely chromium free.

- Zero Chromium S has tones close to those of colored chromate, and Zero Chromium SB has similar tones to black chromate.

- For rack-and-pinion plated items, S was superior to SB in corrosion resistance.

- Even in unplated areas the corrosion resistance is excellent.

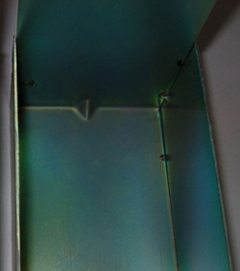

- Example with a housing configuration

- Comparative merits of various rust-resistant coatings

|

|

||

| Zero Chromium S | Colored Chromate | Zero Chromium SB | Black Chromate |

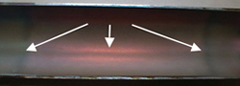

The example shows a pipe interior, one treated with Zero Chromium S and one treated with trivalent chromium.

|

|

| untreated area tannic acid film forms | untreated area trivalent chromium film unformed |

| ※Tannic acid unites not only with zinc,but also with iron. | ※Trivalent chromium does not unite with iron, leaving it exposed. |

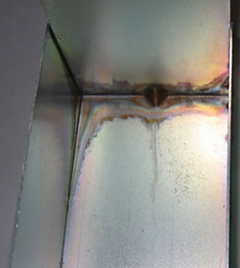

After 4 days of outdoor exposure

|

|

| No red rust development | Red rust development |

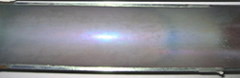

8 hours after saline atomizing testing

|

|

| Slight red rust development | Red rust development |

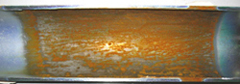

After 9 days of outdoor exposure

| Zero Chromium S treated item | Trivalent chromium treated item |

|

|

| No rust formation | The thinly plated area results at the time of trivalent chromium treatment when zinc is dissolved with a strong acid exposing the underlying iron, so rust forms. |

★1.Since it contains miniscule quantities of hexavalent chromium, there is the danger of natural oxidization into hexavalent chromium after disposal.

★2.The PH control range is narrow, making PH control apparatus indispensable.

★3.Blending with miniscule quantities of copper or iron etc, causes treatment liquid to age.

★4.It is prone to have by a product of hexavalent chromium in waste water treatment.

surface treatment technnology

- Zero Whisker S

- Zero Chromium

- Concerning hazardous substances in Zero Chromium

- Concerning surface resistance in Zero Chromium

- Concerning the friction factor in Zero Chromium

- Concerning the corrosion resistance of un plated areas

- Zinc plating

- Nickel plating

- Electroless nickel plating

- Tin plating

- Aluminum chemical conversion treatment

- System of keeping